SL Tight Head

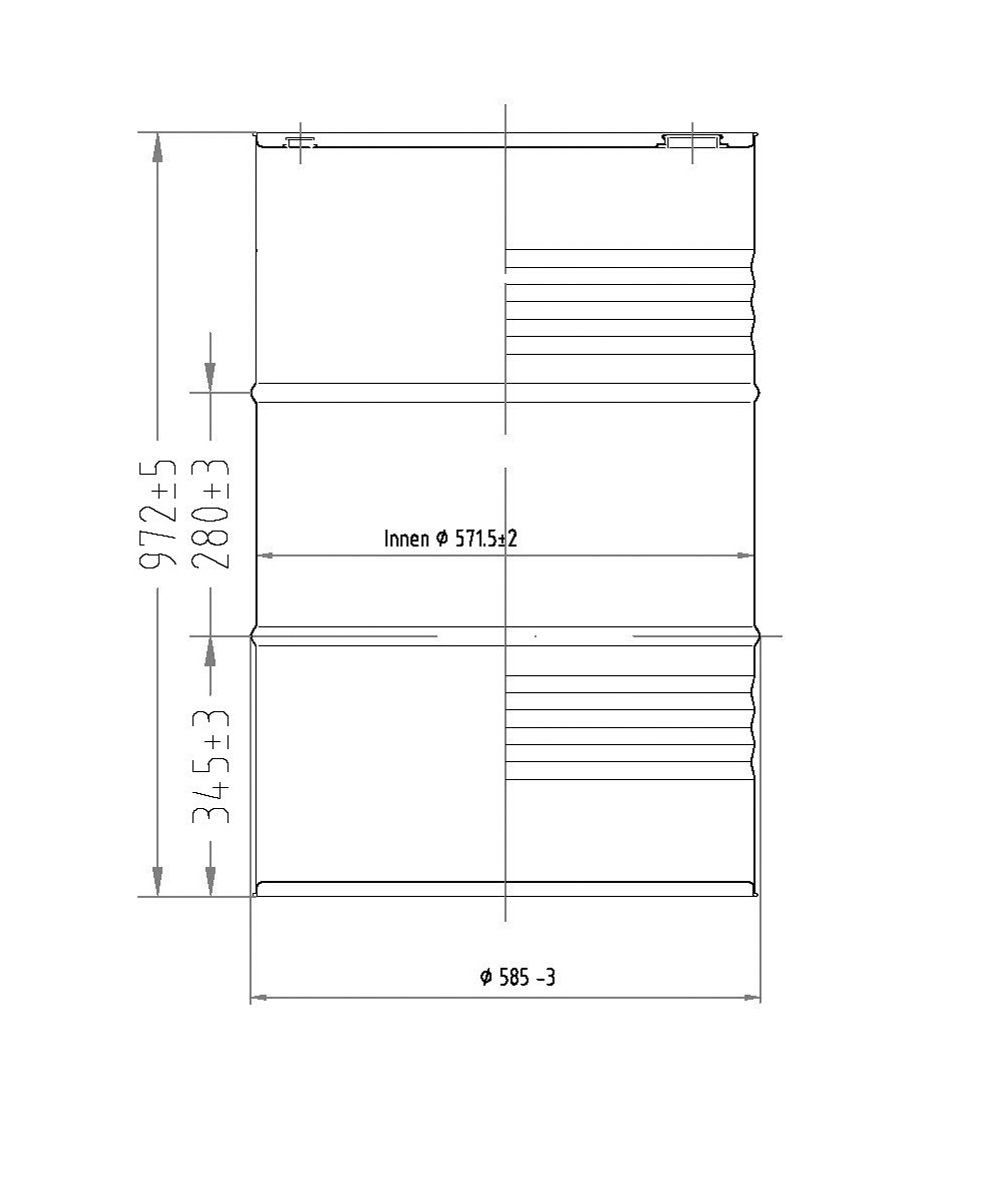

Steel Drum SFF 235 L

The SL SFF 235 Tight Head Steel Drum transfers today’s market requirements into the optimum packaging size for steel drums by filling the free spaces during transport with additional height, thus achieving more than 10% additional filling volume with only 5% more packaging weight, and this without any loss in performance, quality and safety requirements.

The diameter continues to comply with the international standard DIN EN 15750. Variants in the sheet thickness, the number and shape of the corrugations and the decorative design adapt the SL Tight Head Steel Drum to almost any performance requirement and offer possibilities for individual design. A safe, homogeneous interior coating protects the environment from aggressive filling goods or follows the highest food law requirements.

SL XL Tight Head Steel Drum are double-coded and are therefore suitable for liquids, pasty goods and solids. Handling is optimally matched to filling, transport, storage and removal. The design requirements for optimum residual emptying have also been taken into account.

ReUse and recycling capabilities of our packaging follow the high standards of modern SL environmental policy.

High-quality drums – Not just yesterday

Quality with history

What began in 1892 with the production of ash buckets and watering cans is now one of the leading specialist companies in the special steel packaging sector. An extraordinary success story, driven by the goal of always developing the best solutions for the most diverse requirements of our customers.