SL Composite drum

SKF 205 L

The SL composite drum 205L combines the high performance of the SL tight head steel drum with the chemical resistance and food suitability of a high quality plastic packaging. The inner container made of high-molecular polyethylene is adapted to the shape of the steel body and complies with the strict specifications of the US Food and Drug Administration (FDA), as well as the European food safety regulations.

To maintain dimensional stability and the highest cleanliness requirements, the inner container is tightly sealed immediately after manufacture and is only folded in after the steel container has been painted. The intermediate space is additionally hermetically sealed with a round seal, made of EPDM.

A ventilation screw connection is optionally available as pressure compensation. The dimensions comply with the international standard DIN EN 15750. Variants in the sheet thicknesses and the mass of the inner container (3.0, 4.5 and 6.0 kg) adapt the SL combi drum to the highest performance requirements. The handling is optimally adapted to filling, transport, storage and removal.

ReUse and recycling capabilities of our packaging follow the high standards of SL’s modern environmental policy.

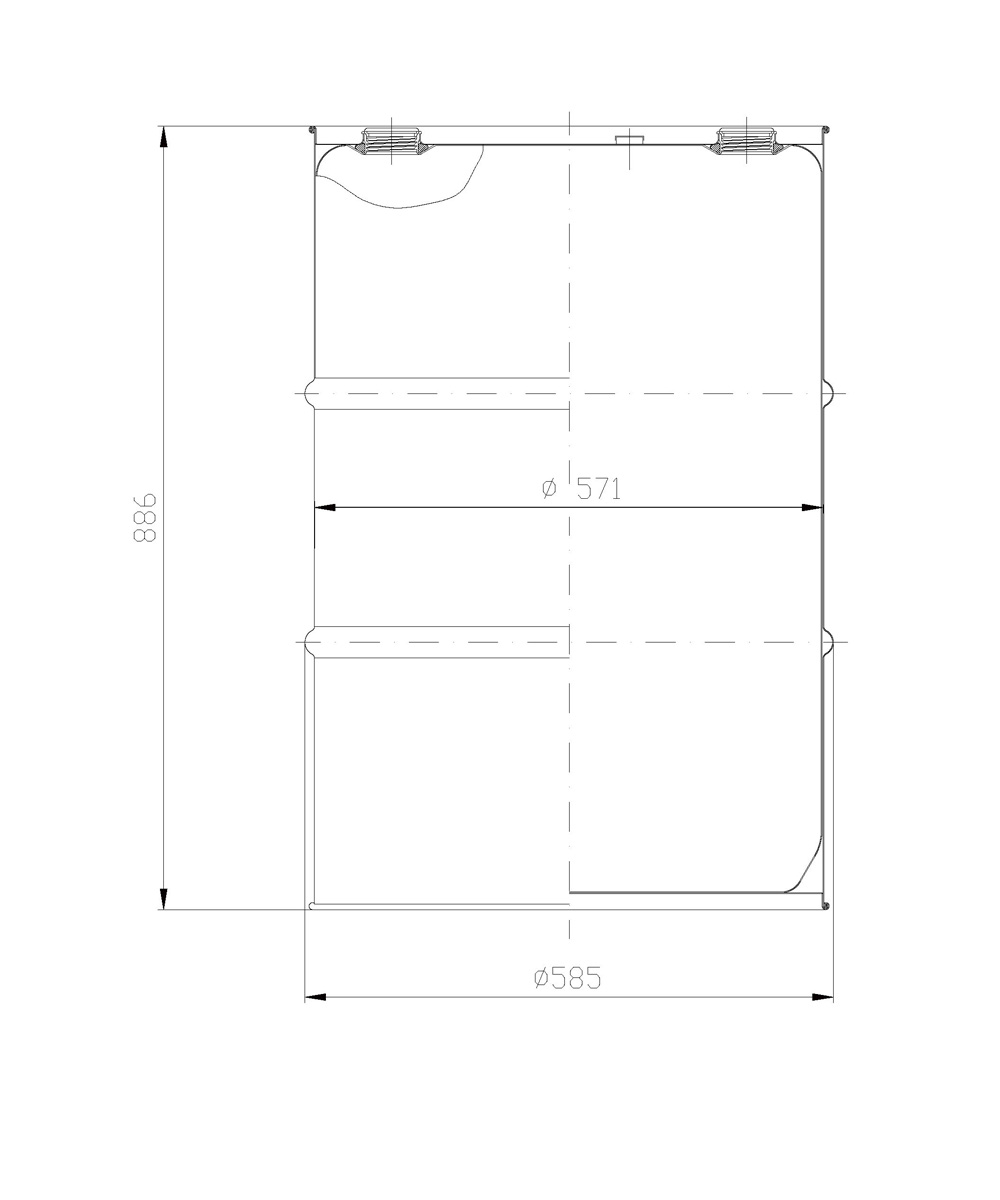

Dimensions:

Filling dimension: Nominal volume: 205 L

Height: 883 +/- 4 mm

Diameter: 585 +0/-3 mm

Technical info:

Made of sheet metal ISO 3574 according to ISO 15750-2.

Body welded, bottoms specially seamed with sealing compound.

Safety lock systems acc. to ISO 15750-3 / plastic

Inner container made of HDPE

High-quality drums – Not just yesterday

Quality with history

What began in 1892 with the production of ash buckets and watering cans is now one of the leading specialist companies in the special steel packaging sector. An extraordinary success story, driven by the goal of always developing the best solutions for the most diverse requirements of our customers.